Now Reading: Sugar Scoop Welding Hood: The Ultimate Guide for Welders (2026)

-

01

Sugar Scoop Welding Hood: The Ultimate Guide for Welders (2026)

Sugar Scoop Welding Hood: The Ultimate Guide for Welders (2026)

Welding requires a careful balance of protection, clear vision, and user comfort to do the job right. And, the helmet you choose plays a pivotal role in determining how effectively and safely you can perform. Among the many types of welding helmets out there, the sugar scoop welding helmet has carved a special place in the hearts of many professional pipe welders and seasoned craftspeople. Ever wondered what a sugar scoop welding hood is and why it stands out? Why is it so popular? And, is it right for you?

In this comprehensive article, we’ll break down everything that you need to know about the sugar scoop welding hoods- starting with their origin, design and what sets them apart in the world of welding.

What is a Sugar Scoop Welding Hood?

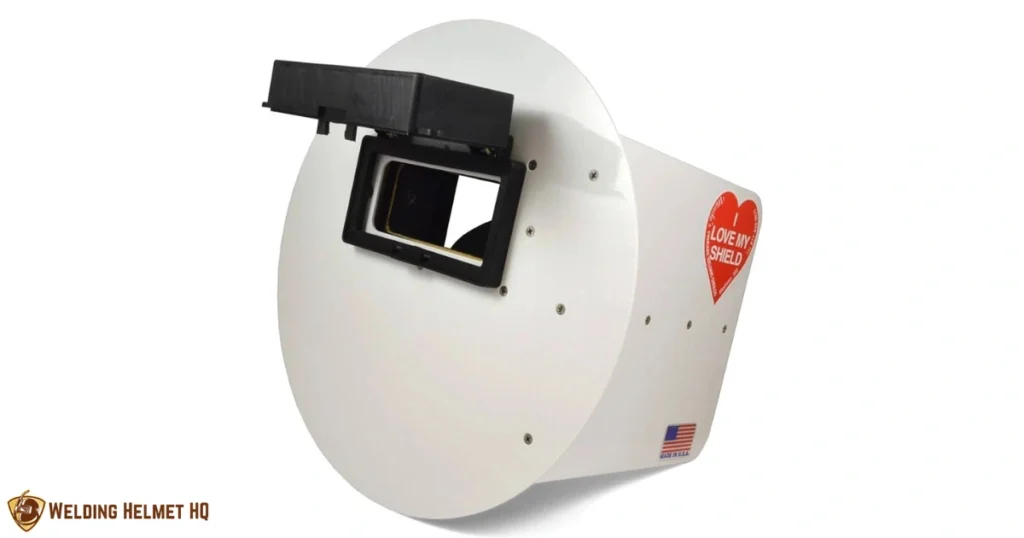

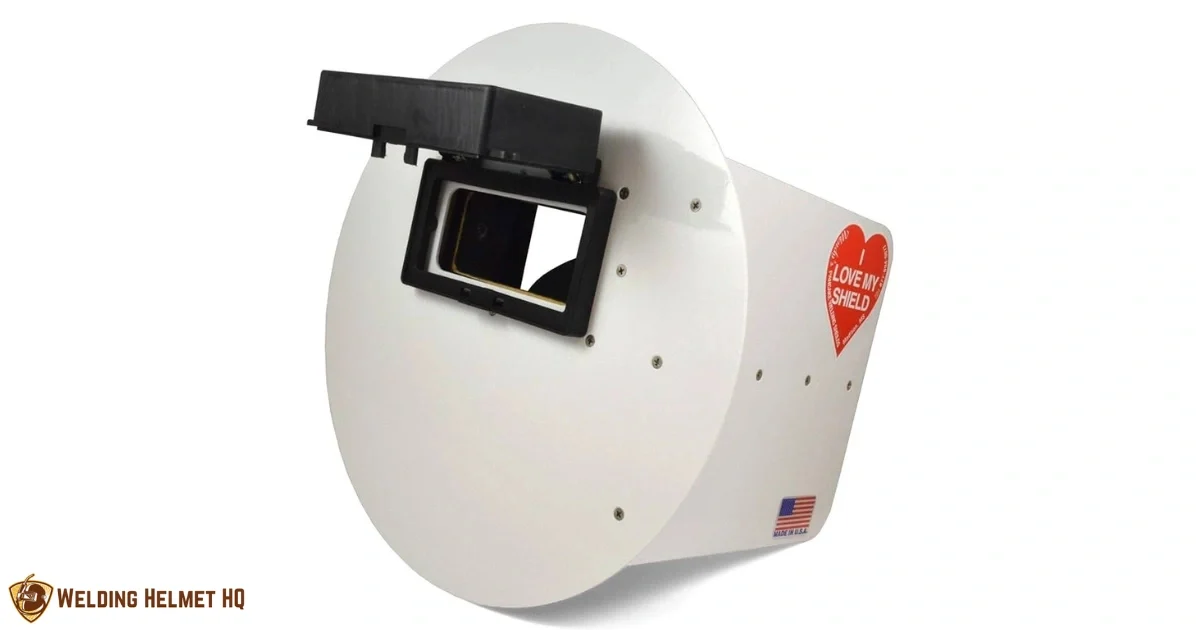

Sugar Scoop welding hood as its name suggests got its nickname from its unique shape, which resembles an old-fashioned sugar scoop used to dig sugar out of barrels. With a longer and narrower face shield compared to standard welding helmets, it offers a streamlined silhouette that extends further outward, making it ideal for tight spaces, particularly for pipe welders.

These welding hoods are designed to be worn low on the face, offering superior neck protection and a clear view of the weld puddle- something that professionals love when doing precision work, especially in field or shop pipe welding applications.

A Brief history and origin of Sugar Scoop Welding Helmets

The sugar scoop helmet has its deep roots in the oil and gas industry, where pipe welding is a daily task. Welders needed a helmet that could:

- Fit into confined areas like between large pipes.

- Provide enough visibility for downhill welding.

- Block UV and IR rays effectively.

- Stay lightweight during long shifts.

Back in the day, sugar scoop welding hoods were often handcrafted by welders themselves, using fiberglass or repurposing pancake and pipe-liner shells. Over time, companies saw the demand and began producing these hoods for commercial use. Their growing popularity has since moved them from niche to mainstream within the welding world.

Key features of Sugar Scoop Welding Hoods

Now, let’s explore what makes the sugar scoop welding hoods unique:

1. Extended Nose Design

The signature sugar scoop design extends forward from the welder’s face, offering more space between the lens and the work area. This allows for better ventilation, reduces lens fogging, and keeps the hood cooler during prolonged welding.

2. Slim and Narrow Shell

Unlike bulky auto-darkening welding helmets, the slim profile helps in tight spots, especially for welders crawling into pipeline trenches, scaffolding, or compact plant rooms.

3. Customizable Fit

Most sugar scoop welding helmets are modular meaning that they support customization with headgear, fixed or flip-up lenses, and sometimes even powered air-purifying respirators (PAPRs).

4. Lightweight Build

Sugar scoop welding hoods are extremely lightweight as they are generally constricted from fiberglass or carbon fiber. That’s why they reduce neck strain which is a common issue among full-shift welders.

5. Lens Positioning

Sugar scoop welding helmets usually have the lens positioned nearer to your eyes than regular welding helmets. This lens positioning is favored for close-up, precision welding, such as TIG or pipe stick welding.

Materials used in Sugar Scoop Welding Hoods

Now, let’s explore the materials used in sugar scoop welding hoods and how they impact strength and functionality:

| Material | Pros | Cons |

|---|---|---|

| Fiberglass | Lightweight, heat-resistant, affordable | It can crack or chip off under impact. |

| Carbon Fiber | Ultra-light, extremely durable | Expensive. |

| Plastic (Rare) | Budget-friendly and easy to mould | Less heat-resistant, not long-lasting. |

| Composite | Balance of durability and weight | Depends heavily on brand and build quality. |

Fiberglass and carbon fiber models are typically recommended for professional use, especially in high-heat environments.

Why Pipe Welders prefer the Sugar Scoop design of welding helmet?

Pipe welding, especially downhill welding using techniques like 6010 root pass, requires extreme precision and constant visibility. Sugar Scoop welding helmets are built to fit snugly around your face and neck, helping to block out light and glare. They stay in place as you move and make it easier to maintain good posture without needing to tilt your head much.

Additionally, the streamlined design allows the welder to walk the cup without the hood getting in the way which is something that standard bucket-style helmets may hinder.

Comparison with Other Welding Hoods

Now, let’s look at the comparison of sugar scoop welding helmets with other types of welding helmets:

Sugar Scoop vs Pancake Hood

| Feature | Sugar Scoop | Pancake Hood |

|---|---|---|

| Application | Pipe Welding (field/shop) | Pipeline Welding (outdoor) |

| Face Coverage | Complete protection for face and neck | Round face shield with side shield |

| Eye Protection | High | Very high especially in sunlight |

| Comfort | Very comfortable and fits better | Comfortable, but less neck support |

| Vision | Closer and clearer with cup-style lens | Limited peripheral vision |

Sugar Scoop vs Traditional Bucket Helmet

| Feature | Sugar Scoop | Standard Helmet |

|---|---|---|

| Design | Extended, scoop-shaped | Boxy, full-head coverage |

| Weight | Lightweight | Heavier, especially with ADF |

| Fit | Snug and compact | Roomy, less suited for tight areas |

| Target User | Pipe welders, fieldwork | General welders, fab shops, hobbyists |

As you can see from the above comparison that sugar scoop welding helmets holds a specific niche but excels at what it was made for which is making it a go-to-gear for serious pipe welders.

Some common modifications that welders make

These sugar scoop welding hoods are quite often modified by welders according to their personal preference. Some of the common customizations include:

- Auto-darkening lenses though some prefer passive lenses.

- Leather head wrap or bibs for extra neck protection.

- With flip-up lens frames, you can quickly switch between grinding and welding without taking your hood off.

- Painted or hydro-dipped shells for personalization.

- Magnifying or cheater lenses for enhanced detail.

Are Sugar Scoop Welding Helmets OSHA approved?

Generally, sugar scoop welding helmets are approved as long as they meet the following:

- ANSI Z87.1 eye protection standard

- Adequate UV/IR filtration in the lens

- Proper fit with the PPE like flame-resisting clothing, gloves, and respirators.

Always double check if your workplace requires specific certification labels or if third-party modifications affect compliance.

How to choose the right Sugar Scoop Welding Hood?

Choosing a sugar scoop welding hood is not just about grabbing one off the shelf. Welders often tailor their hood to suit their personal welding style, work environment, and even comfort preferences. When picking out a sugar scoop welding hood, keep these key things in mind:

1. Material and Weight

- The most commonly used material for these hoods is Fiberglass because of its durability and lightness. Fiberglass made hoods are tough against heat but can crack if dropped.

- Carbon fiber, known for its light weight and durability, typically comes at a higher cost. It is ideal for welders who weld for long hours daily.

- Avoid any plastic hoods unless you’re on a tight budget or only welding casually as they won’t withstand industrial work.

Tip: Go for a sugar scoop welding hood that feels light on your head but can still handle tough jobs without falling apart.

2. Lens Compatibility

You’ll need to make a choice between two lens options, depending on your preferences and requirements.

- Fixed Passive Lens: Fixed lens hoods are still a go-to for many welders—basic, durable, and built to last.

- Auto-darkening lens (ADF): It is convenient for switching between tasks, but adds weight and needs battery maintenance.

Ensure the hood you choose or buy can accommodate standard size lenses (like 2 inch x 4.25 inch) or a flip-up setup if you use a grind mode.

3. Field of Vision

A closer lens-to-eye distance gives a more accurate view of the weld puddle, which is critical in pipe and TIG welding. Make sure to evaluate the hood’s shape and depth, as these factors influence both side visibility and overall wearing comfort.

4. Headgear Support

Some hoods come with basic headgear that’s fine for light-duty welding but if you’re welding all day or a professional welder, then, invest in:

- Adjustable ratcheting headgear

- Cushioned headbands

- Flip-up front holders

Several brands provide headgear that, with some minor adjustments, can be fitted into sugar scoop shells.

5. Brand and Build Quality

Not every sugar scoop welding hoods offers the same quality or features. So, look for well-reviewed brands which have a strong reputation in the welding community.

6. Helmet Size and Fit

Since sugar scoop welding hoods rest lower and closer to the neck and shoulders, they should:

- Leave enough space for respirators or neck bibs.

- Not dig into your shoulders.

- Stay secure while nodding or adjusting.

Setting up your Sugar Scoop Welding Hood

Once you’ve picked or chose the perfect hood, it’s time to set it up. Given below is a basic walkthrough to set up your hood:

Step 1: Install the Headgear

Most sugar scoop welding hoods allow aftermarket headgear to be bolted or clamped inside. So, make sure:

- Its centered properly for weight balance.

- The headband is tailored to fit securely while still ensuring comfort during use.

- Make sure that the flip-up or nod-down mechanism operates smoothly without any resistance.

Step 2: Add the lens and filter

Selecting the right lens is crucial for achieving clear vision and proper protection from arc radiation:

Lens Setup includes:

- Outer Clear Cover Lens – Protects the main filter by blocking sparks, spatter, slag, and dust during welding.

- Welding Filter Lens (Shade 10-13) – Either passive or auto-darkening.

- Inner lens or Cheater lens (optional) – Acts like reading glasses for better visibility.

Installation Tip: Always make sure the lenses sit flush and don’t rattle. As dust or improper sealing can distort your vision and may introduce safety risks.

Step 3: Customize for comfort ad utility

Many welders like to customize their hoods with leather neck bibs or flame-resistant wraps, ventilation holes, anti-fog coatings or anti-reflective covers and personal paint jobs or stickers.

While doing all these modification just make sure that it does not interfere with safety standards or block your vision.

Wearing a Sugar Scoop Welding Hood Correctly

Wear your sugar scoop welding hood correctly to get the most out of it:

- Position the hood low on your nose bridge, allowing the nose guard and front lip to sit just in front of your chin.

- Make sure your jacket collar is tucked into the hood so stray sparks and bright flashes don’t slip through.

- Wear a balaclava or a flame-resistant hoodie under the helmet for full protection when working outdoors.

The design of sugar scoop welding hoods may feel unfamiliar at first but within a few uses many welders find it becoming their second nature.

How to maintain your Sugar Scoop Welding Hood?

Taking care of your welding hood not only improves its longevity but also the overall welding experience. Here’s how you can also take care of your welding hood:

1. Clean the lens regularly

- Use lens wipes or a microfiber cloth.

- Skip the strong cleaners—some of them can scratch up your lens and mess with visibility.

- Replace cover lenses as soon as they’re visibly damaged or foggy.

2. Inspect for damage

Check your hood after every welding job:

- Replace or repair if any cracks in the shell.

- Tighten screws or replace the band, if found headgear loosen.

- If the lens get misaligned, reposition it immediately to avoid any eye strain or injury.

3. Store in a Safe Place

Always keep your hood in a padded helmet bag, a dust-free, cool environment and away from high-moisture areas to prevent mold on the headbands. You can also install wall-mounted hooks or helmet hangers in your shop or near your welding table.

4. Replace Headgear Pads and Bands

Replace your headgear pads periodically especially in hot working conditions or long shifts. As sweat-soaked pads lose cushioning and can lead to headaches.

5. Check the fasteners

Welding hoods that rely on side tension knobs for up or down movement can wear out quickly. Make sure the screws are snug and the flip-up lens stays put—it shouldn’t drop down or wiggle while you’re working.

6. Avoid Unauthorized Modifications

Welding helmet manufacturers design their gear to meet safety standards. DIY modifications like cutting ventilation slots or enlarging the lens opening can invalidate those standards and put your safety at risk.

If you really want to modify your hood then, do it very carefully and only after understanding the risk.

Troubleshooting Common Issues

| Problem | Likely Cause | Solution |

|---|---|---|

| Fogging lens | Poor ventilation or no anti-fog lens | Use anti-fog spray, ventilated hood |

| Blurry Vision | Dirty lens or wrong shade | Clean lens or change filter |

| Neck Fatigue | Heavy hood or poor headgear | Upgrade to lighter shell/headband |

| Lens not staying in place | Loose holders or worn clips | Replace clips or tighten holders |

| Insecure fit | Worn headband or misalignment | Replace or adjust headgear |

Pros and Cons of Sugar Scoop Welding Hoods

Let’s also see the pros and cons of these hoods so you can make an informed decision before committing to one.

Pros:

| Benefit | Description |

|---|---|

| Excellent Visibility | The closer lens and the extended design reduce glare and allow clearer view of the weld puddle. |

| Great for Tight Spaces | The narrow profile fits easily between pipes and structural components. |

| Lightweight | Fiberglass or carbon-fiber construction reduces neck fatigue during long shifts. |

| Customizable | Easily modified with flip-up lenses, cheaters, bibs, and decals. |

| Comfortable Fit | Made to fit firmly on the face without being heavy or bulky. |

| Low Glare | Its shape naturally shields stray light, especially useful during outdoor or sunny work. |

Cons:

| Drawback | Description |

|---|---|

| Limited Auto-darkening Compatibility | Many sugar scoop hoods are not built to support auto-darkening lenses. |

| Not ideal for Overhead Welding | Lack of full top coverage can be a hazard for overhead sparks. |

| Customization may void safety certifications | Modifying too much can risk compliance with OSHA/ANSI. |

| Initial Adjustment Period | New users may feel awkward switching from traditional bucket helmets. |

| Less Head Protection | Doesn’t wrap fully around the head like full-coverage welding helmets. |

Use cases and Ideal Work Environments

Sugar Scoop welding hoods are not meant for everyone but in the right hands and environment, they’re truly unbeatable.

1. Pipe Welding (Field & Shop)

- Perfect for downhill stick welding (6010/7018).

- Thin design fits between pipes and helps keep your neck steady.

- Extremely popular among oil and gas welders, power plant fabricators, and structural pipefitters.

2. TIG Welding

- Having the lens closer to your eyes makes it easier to see the weld puddle clearly, which really helps with TIG welding.

- Works well for delicate stainless, aluminum, and titanium welds in confined tanks or frames.

3. Structural Welding

- Great for welders working around rebar cages, tight scaffolding, or narrow joints in steel frame buildings.

4. On-site Welding

- Light and easy to carry, great for field-jobs where auto-darkening lenses might be too delicate or unsuitable.

Not Ideal For:

- Overhead or vertical flux-core welding due to the limited top coverage.

- High-amperages industry shop work involving grinding, cutting, and plasma.

- General fabrication work that needs multi-tasking (grind/weld/cut) frequently with ADF hoods.

Pro tips from experienced welders

Here’s what seasoned welders say after years of using sugar scoop welding hoods:

“Invest in your lenses”

Always keep your outer and inner cover lenses clean as on blurry lens can wreck your entire weld. Also keep spares in your toolbox.

“Drill tiny air holes – carefully”

Some welders drill 2-3 mm vent holes in their scoop helmet’s side to reduce fogging, but only after testing on scrap. Don’t ruin your hood’s structure.

“Keep your setup consistent”

Once you find a lens height, strap tightness, and viewing angle that works. Then, stick with it. As muscle memory is key to faster setup and better welds.

“Customize with pride”

Paint or sticker your hood! Just make sure any artwork doesn’t interfere with safety. Customization boosts morale and helps identify your gear easily.

“Auto-darkening isn’t always better”

Pipeline welders frequently rely on passive lenses due to their consistent performance in harsh and unpredictable weather. ADF batteries can die unexpectedly during long shifts.

Final Thoughts

Sugar Scoop Welding Hood is much more than just a cool-looking welding helmet. It is a performance driven upgrade for serious welders who want comfort, clarity, and control. Whether you’re welding in a refinery pipe rack, fabricating in a field rig, or just doing precise TIG welding in tight quarters, this helmet has something valuable to offer.

It may take a few days to get used to the profile and fitting of this helmet but once you do then, you’ll never go back to those bulky traditional heavy lids helmets again.