Now Reading: What is a Pancake Welding Hood? Everything You Need to Know

-

01

What is a Pancake Welding Hood? Everything You Need to Know

What is a Pancake Welding Hood? Everything You Need to Know

When it comes to precision welding in outdoor or high-light environments, it isn’t just a matter of convenience to have a right set of equipment but it is also a matter of safety, comfort and performance. Among all the tools that professional welders swear by the most, particularly in pipeline and structural welding, is the Pancake Welding Hood, also referred to as a Pancake Welding Helmet.

These uniquely designed protective helmets have a distinctive look, an interesting history, and they serve a vital function in shielding the welder’s eyes and face while providing unmatched comfort and performance in demanding environments.

Whether you are a beginner welder or an experienced pipe welder, looking to upgrade your gear, this is the guide which will help you to understand about the importance of pancake welding helmets in welding profession.

What is a Pancake Welding Hood?

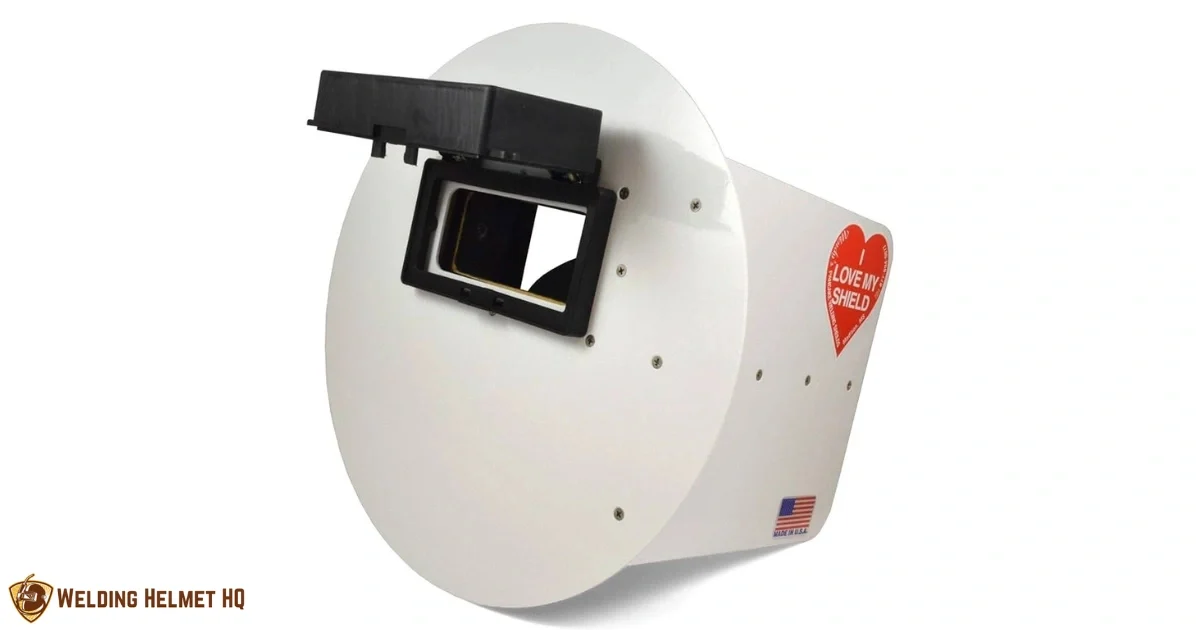

Pancake welding hoods are built mainly for outdoor welding—especially pipeline work—where you’re dealing with bright sunlight and windy conditions. It gets its name from its flat-faced, circular shape that resembles a pancake.

Pancake hoods are more minimalistic, offering protection focused primarily around the face and eyes. Unlike traditional welding helmets that cover and protect the entire face and sometimes the head.

The standout feature of the pancake welding hood is its face shield paired with a side box, designed to hold the lens and shield one side of the welder’s face from arc flash and glare. This side box can be customized according to the welder or user, like if it is used by left-handed welder then, the side box will be on the right side and vice versa. The reason why this helmet is so effective for certain type of welding methods is because of its asymmetrical design.

Brief History of Pancake Welding Helmet

Pancake welding hoods originated from pipeline welding practices, especially in the southwestern region of the United States. The high-intensity outdoor environment, combined with the long hours and precision-required welds, led to the development of a helmet that could provide better protection from sunlight and UV rays, be lightweight and more comfortable to use during the challenging angles involved in pipe welding.

Over the decades, these pancake hoods have evolved from handmade wooden helmets to highly customized, professional-grade equipment made of lightweight and durable materials such as balsa wood, phenolic resin or carbon fiber.

Key features of a Pancake Welding Hood

To know why these pancake welding helmets are favored by so many professionals, it is important to understand the components and design of that. Given below are some of the critical features of a pancake welding hood:

1. Flat Front Face Plate

The round, flat front is one of the most identifiable features. The curved front shield helps block out harmful UV and infrared rays from hitting your face. Its flatness is intended to reduce weight and maintain a compact form, which helps in tight working conditions like pipelines.

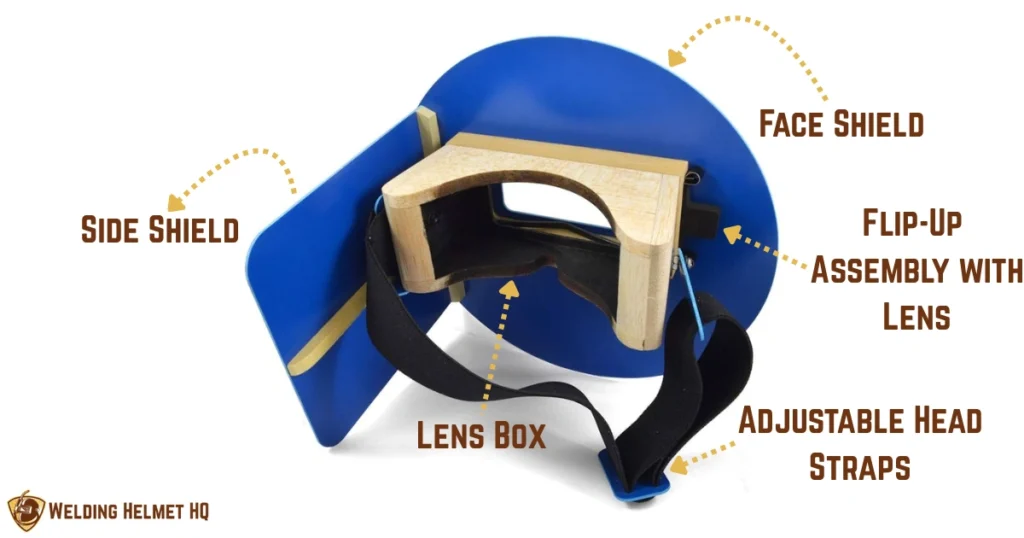

2. Lens Box

The lens box holds the welding lens and often features a flip-up design for ease of viewing the workpiece when not actively welding. The lens box is usually made from lightweight balsa wood, which provides insulation against heat and doesn’t conduct electricity.

3. Side Shield (Eye Box)

The side shield significantly reduces the eye strain and adds to the overall comfort of the welder by blocking peripheral light, arc glare, and sunlight, making it ideal for outdoor use.

4. Adjustable Head Straps

Most pancake welding helmets comes with a customizable head strap to fit different head sizes, ensuring comfort during long working hours.

5. Lightweight Construction

Pancake hoods are lighter than normal welding helmets, so they’re easier to wear. This light weight of these helmets as many models weigh even less than a pound which help to reduce neck fatigue and strain over extended periods.

Pancake Welding Hoods vs Traditional Welding Helmets

Let’s look at the table below to understand how pancake welding helmets are different from traditional welding helmets:

| Feature | Pancake Welding Hood | Traditional Welding Helmet |

|---|---|---|

| Weight | Lightweight(often < 1lb) | Heavier(2-4 lbs or more) |

| Design | Minimalistic design with side shield | Full face and head coverage |

| Use Case | Outdoor, pipeline, field welding | Shop, fabrication, general welding |

| Customization | Right / Left-handed versions | Universal |

| Sunlight Protection | Excellent | Moderate to good |

| Lens Visibility | Fixed or flip-up | Auto-darkening often available |

| Comfort | High for field use | Better for indoor, varied tasks |

As we can clearly understand that Traditional helmets offer greater protection and flexibility for a wide range of welding tasks. Pancake welding helmets are purpose-built for high-precision, outdoor welding which makes them irreplaceable in those settings.

Who uses Pancake Welding Hoods?

Pancake welding hoods are mostly used by:

1. Pipeline Welders

Pipeline welders often work outdoors under the sun for extended hours. The anti-glare, lightweight features of pancake hoods make them ideal for such environments.

2. Structural Welders

Since pancake hoods are light, you can move your head around more easily than with heavier welding helmets. That’s why it becomes a necessity when working in high, tight, or awkward positions.

3. Certified Welding Inspectors(CWI)

Certifies Welding Inspectors or CWIs also prefer pancake hoods for their lightweight and visibility advantages when inspecting pipelines and weld joints in the field.

4. Welders in remote or rugged environment

If the terrain is uneven, dusty, or subjected to weather extremes, the compact and rugged design of pancake welding helmets comes in handy.

Advantages/Benefits of using a Pancake Welding Helmet

The main advantages or benefits that make pancake hoods a favorite among professional welders are:

- Reduced Glare: The built-in side box and close faceplate minimizes eye fatigue by reducing or blocking the outside light.

- Enhanced Precision: The minimized weight and snug fit let the welders focus on precise movements without any bulky distractions.

- Better Airflow: Pancake hoods offer better ventilation than traditional helmets that covers the head completely, which is essential for hot outdoor conditions.

- Ergonomic Comfort: These hoods can be easily worn by welders for hours without experiencing the same level of neck strain associated with heavier traditional welding helmets.

- Customization Options: Pancake hoods can be customized to personal welding style from selecting left or right-hand setups to choosing materials and lens types.

Disadvantages/Drawbacks of using Pancake Hoods

Although pancake hoods or pancake welding helmets have numerous advantages but there are also few limitations or disadvantages of using it. Such as:

- Limited face and head protection: These helmets don’t cover the top or back of the head which may be a safety concern in some environments.

- Not Ideal for Overhead Welding: They aren’t suitable for overhead tasks due to their minimal coverage as sparks and debris might fall onto the head or neck.

- Fewer Auto-Darkening Options: Most pancake hoods use fixed-shade lenses, though some models nowadays started using auto-darkening lenses.

Choosing the right Pancake Welding Hood

Keep the following factors in mind to choose the right pancake welding hood:

1. Material

- Side boxes made of Balsa Wood are lightweight and traditional.

- Phenolic resin or crabon fiber options offer enhanced durability and heat resistance.

2. Lens Compatibility

Whether fixed or auto-darkening, ensure that the hood supports the shade and size of the lens preferred by you.

3. Hand Orientation

Make sure to choose or select the hood built according to your hand orientation, i.e., which ever welding you do right or left hand welding.

4. Strap and fit

For long-term comfort, just look for adjustable straps and padding.

5. Brand Reputation

Stick to reputable or reknowned brands known for quality welding gears.

Maintenance and Care Tips for using Pancake Welding Hoods

The life of your pancake welding helmet will depend on your care and maintenance of it. Want your pancake welding hood to last longer? Try these simple care tips.

- Make it a habit to clean out the lens area to stop dust and debris from collecting over time.

- Keep an eye on the head straps—swap them out if they start looking worn or loose.

- Keep your helmet in a cool, shaded spot where it stays dry and isn’t exposed to sunlight.

- Check the lens to ensure it is properly secured and not scratched before each welding job.

Modifications you can do on your Pancake Welding helmet

May welders like to customize their welding gear and yes you can also customize your pancake welding hood if you want. Want to get more out of your pancake hood? Try these simple ways to make it suit your needs better:

- Do custom paint jobs or decals

- Apply cushioned headbands

- Fit magnifying (cheater) lenses

- Do Anti-fog coatings on lens

- Use Auto-darkening retrofits

These modifications can make your hoods special and stylish.

Conclusion

Pancake welding hood or pancake welding helmet is not just a quirky-looking piece of gear but it is an indispensable tool for thousands of welders who demand precision, comfort, and protection in rugged conditions. It is the go-to choice for outdoor and pipeline welders because of its lightweight construction, field-ready durability and glare-reducing design.

It is not suitable for every type of welding job but it surely outperforms traditional helmets when it comes to outdoor and pipe welding. Whether you are a seasoned professional or just a beginner in welding, having a high-quality pancake welding helmet can significantly improve your comfort and performance on the job.