Now Reading: Leather Welding Helmet: Complete Guide to Protection, Comfort, and Performance

-

01

Leather Welding Helmet: Complete Guide to Protection, Comfort, and Performance

Leather Welding Helmet: Complete Guide to Protection, Comfort, and Performance

When it comes to welding, choosing the right helmet is one of the most important safety decisions you can make. While auto-darkening helmets, pancake hoods, and fiberglass options are widely used, one type stands out for its unique combination of flexibility, comfort, and traditional craftsmanship-the leather welding helmet. Unlike rigid helmets, a leather hood is lightweight, foldable, and particularly popular among pipefitters, boilermakers, and welders who work in tight or awkward positions.

In this in-depth guide, we’ll explore what leather welding helmets are, their advantages, different types, features to consider, and how they compare to modern welding helmets. By the end, you’ll have all the information needed to decide if a leather hood is the right choice for your welding needs.

What is a Leather Welding Helmet?

A leather welding helmet (sometimes referred to as a leather hood or leather shield) is a protective face covering made from heat-resistant leather material. Instead of being built from rigid plastic or fiberglass, these helmets are sewn together from thick, flame-retardant leather panels, often reinforced with stitching and sometimes fitted with a metal or plastic lens holder for welding filters.

Key characteristics include:

- Flexible design – can fold or bend to fit into tight spaces.

- Lightweight feel – often much lighter than traditional helmets.

- Heat and spark resistance – high-quality leather resists burning and charring.

- Custom fit – many welders find them more comfortable for long shifts.

These helmets are particularly valued by pipe welders and those working in industries where space is limited and sparks fly in all directions.

Why Welders Choose Leather Welding Helmets?

So why would a welder choose leather over a traditional rigid helmet? The answer lies in the specific advantages these helmets offer.

1. Lightweight & Confortable

Rigid welding helmets can weigh a pound or more, causing neck strain and fatigue during long shifts. Leather helmets, being soft and flexible, weigh significantly less and distribute weight comfortably around the head. This makes them ideal for welders who spend 8-12 hours on the job daily.

2. Flexibility in Tight Spaces

Pipefitters, shipyard welders, and field welders often work in cramped positions where a traditional helmet won’t fit. Leather helmets bend over and contour around surfaces, allowing welders to get into tight corners without compromising protection.

3. Heat Resistance

Leather is naturally resistant to high heat and sparks, making it a trusted material for welding apparel. A quality leather hood can withstand flying spatter without melting or cracking – something plastic helmets are more prone to.

4. Durability & Longetivity

While a plastic hood may crack or break after heavy use, leather helmets typically wear down more gradually. Many welders report using the same leather hood for years, with only occasional repairs or stitching touch-ups.

5. Traditional Appeal

For many seasoned welders, using a leather helmet is not just about function – it’s about tradition. Leather hoods have been around since the early days of welding and remain a symbol of skilled craftsmanship in the trade.

Types of Leather Welding Helmets

Leather Welding Helmets are not all the same. They come in different styles, shapes, and levels of coverage to suit various applications. Here are the main types:

1. Full Leather Hoods

- Provide complete face and head protection.

- Feature a lens opening with flip-up or fixed glass.

- Best for heavy-duty welding and overhead work.

2. Half Leather Hoods

- Cover only the face area.

- More breathable and lightweight.

- Ideal for spot welding or low-intensity work.

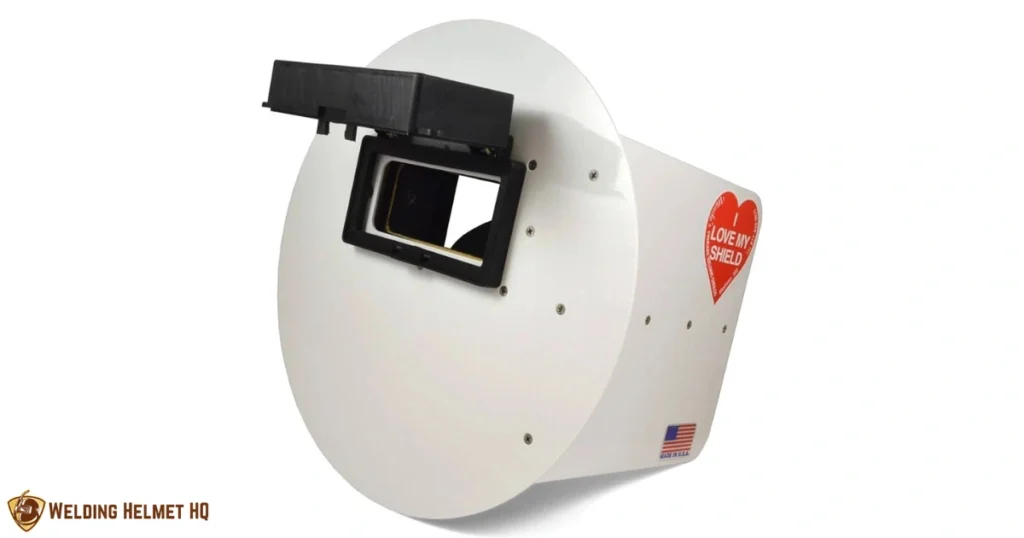

3. Pancake-style Leather Helmets

- Inspired by pancake hoods but made with leather sides and shields.

- Popular among pipe welders for working outdoors and in windy conditions.

- Feature a side shield (usually right or left-handed).

4. Hybrid Leather & Fiberglass Hoods

- Combine rigid fiberglass front with a leather back flap.

- Provide both structure and flexibility.

- Useful when you need extra durability with comfort.

Key Features to Look for in a Leather Welding Helmet

If you’re considering buying one, here are the most important features:

1. Leather Quality

- Choose helmets made from cowhide or split leather, as they offer maximum heat resistance.

- Softer leather = more comfort, but stiffer leather = more durability.

2. Lens holder

- Should support standard welding lenses (shade #8 to #14 depending on process).

- Some models offer flip-up lenses for grinding and inspection.

3. Headgear Fit

- Many leather hoods use elastic straps or adjustable bands instead of traditional ratcheting headgear.

- Check for comfort and snugness.

4. Ventilation

- Since leather can trap heat, a good helmet should include air vents or breathable stitching.

- Some welders even modify theirs for better airflow.

5. Flame & Spark Protection

- Look for helmets with reinforced stitching and treated leather to resist fire damage.

Pros and Cons of Leather Welding Helmets

Like any welding gear, leather helmets have both advantages and disadvantages.

Pros:

- Lightweight & comfortable.

- Excellent for confined spaces.

- Durable under heat & sparks.

- Flexible & easy to carry.

- Long-lasting with proper care.

Cons:

- Not as impact-resistant as rigid helmets.

- Limited auto-darkening options (mostly fixed shade).

- Can feel hot in warm climates.

- Less protection against falling debris compared to hard-shell helmets.

Who Should Use a Leather Welding Helmet?

Leather welding helmets are not for everyone. They are most beneficial for:

- Pipefitters – Welding in cramped pipe racks.

- Field welders – Especially those working outdoors or in ditches.

- Shipbuilders – Maneuvering in tight hull spaces.

- Boilermakers – Working around tanks and confined areas.

- Old-school welders – Who prefer tradition over technology.

On the other hand, if you mostly weld in a shop, do heavy grinding, or require auto-darkening lenses, you may find a rigid helmet more practical.

Leather Welding Helmets vs Modern Auto-Darkening Helmets

One of the most common debates among welders is whether to go traditional with a leather hood or embrace the modern convenience of auto-darkening helmets. Both have advantages, and the right choice depends largely on your work environment and personal preference.

1. Weight & Comfort

- Leather Welding Helmet – Extremely lightweight, flexible, and less fatiguing. Welders working 8-10 hours daily in tight spaces appreciate the comfort.

- Auto-Darkening Helmet – Heavier due to electronics, sensors, and rigid shells. However, premium models balance weight with comfort-focused headgear.

2. Durability

- Leather Welding Helmet – Resistant to sparks, heat, and general wear. Stitching may wear out over time, but leather itself remains durable.

- Auto-Darkening Helmet – While strong, rigid helmets can crack under impact or extreme heat. Electronics may also fail over time.

3. Lens Technology

- Leather Welding Helmet – Typically uses fixed shade lenses. Welders must manually swap lenses or flip them up when not welding.

- Auto-Darkening Helmet – Features advanced auto-darkening filters (ADF) that adjust shade instantly when an arc is struck. Excellent for tasks requiring frequent stops and starts.

4. Suitability for Environments

- Leather Welding Helmet – Perfect for tight spaces, pipe welding, and fieldwork where flexibility matters.

- Auto-Darkening Helmet – Best for shop welders, fabricators, and frequent tack welding.

Verdict

If you value tradition, lightweight comfort, and durability in harsh conditions, a leather welding helmet is the better choice. But if your work demands precision, frequent switching, and modern convenience, auto-darkening helmets win. Many professional welders own both types for different jobs.

Safety Standards for Leather Welding Helmets

Like all PPE, welding helmets must meet specific safety standards. Since leather helmets are less common than rigid helmets, not all models carry certifications, but here are the key standards to look for:

1. ANSI Z87.1 (U.S.)

- Sets requirements for eye and face protection.

- Ensures the welding filter lens provides correct shade and impact resistance.

2. CSA Z94.3 (Canada)

- Canadian standard for protective eyewear.

- Often adopted in North America alongside ANSI compliance.

3. EN 175 (Europe)

- Specifies welding face protection requirements.

- Covers aspects like resistance to hot sparks and optical performance.

4. AWS Recommendations

The American Welding Society (AWS) emphasizes using helmets that provide:

- Proper optical shade for each welding process.

- Heat and spark resistance.

- Adequate coverage for face and neck.

Important Note: Some budget leather hoods (especially unbranded ones) may not carry official certifications. Welders should verify compliance before purchase, particularly if working under OSHA or company-regulated environments.

Maintenance & Care Tips for Leather Welding Helmets

Leather Welding Helmets, like leather gloves or jackets, require proper maintenance to extend their lifespan. Neglecting care can cause them to harden, crack, or lose flexibility.

1. Cleaning

- Remove dust and debris after every use.

- Use a damp cloth – avoid soaking leather in water.

- For stubborn grime, use a mild leather cleaner.

2. Conditioning

- Apply leather conditioner (such as mink oil or saddle soap) occasionally to prevent drying out.

- Avoid over-conditioning, as it may soften leather too much and reduce durability.

3. Storage

- Store in a cool, dry place.

- Keep away from direct sunlight and excessive moisture.

- Avoid folding it unnecessarily to prevent creasing.

4. Lens Maintenance

- Inspect welding lenses regularly for cracks or scratches.

- Clean with lens-safe wipes to maintain clear visibility.

- Replace damaged or foggy lenses immediately.

Best Practices When Using a Leather Welding Helmet

Even with a durable hood, safe use requires certain best practices:

1. Choose the Right Shade Lens

- Stick Welding (SMAW) – Shade 10-12.

- MIG Welding (GMAW) – Shader 10-13.

- TIG Welding (GTAW) – Shade 9-12 (lower amperage may allow lighter shades).

- Plasma Cutting – Shade 5-9.

Using too light a shade can cause arc eye, while too dark a shade can strain vision.

2. Wear Additional PPE

Leather hoods only protect the face. Always pair them with:

- Welding jacket or sleeves (leather preferred).

- Gloves resistant to heat and spatter.

- Respiratory protection in poorly ventilated areas.

3. Modify for Comfort (if needed)

Many welders customize their hoods with:

- Extra ventilation holes (carefully punched).

- Elastic headbands for better fit.

- Flame-retardant liners for added comfort.

4. Regular Inspections

Before each job:

- Check for stitching damage.

- Ensure the lens holder is secure.

- Replace worn straps or bands.

Common Problems with Leather Welding Helmets & Fixes

Even high-quality leather hoods can face issues. Here’s how to address them:

Problem 1: Lens Holder Becomes Loose

- Fix: Reinforce with screws, rivets, or replace with a new lens frame.

Problem 2: Leather Stiffening

- Fix: Apply leather conditioner and gently massage until flexible again.

Problem 3: Heat Build-up Inside

- Fix: Add small vent holes or wear a moisture-wicking bandana underneath.

Problem 4: Poor Fit

- Fix: Replace straps with adjustable elastic or padded headgear.

Problem 5: Limited Auto-Darkening Options

- Fix: Some companies sell auto-darkening insert lenses compatible with leather hoods. These upgrades are worth considering if you prefer modern features.

Leather Welding Helmets in Specialized Welding Environments

Leather hoods shine in certain jobs more than others. Here’s how they perform in various scenarios:

1. Pipe Welding

- Why Ideal: Slim, flexible, and allows welders to position themselves around pipes easily.

- Key Feature Needed: Side shield (right or left) for sun and wind protection.

2. Shipbuilding

- Why Ideal: Tight spaces inside hulls demand lightweight, bendable helmets.

- Key Feature Needed: Full coverage with flame-resistant stitching.

3. Oilfield & Field Welding

- Why Ideal: Portable, rugged, and not easily damaged when carried around.

- Key Feature Needed: Tough cowhide construction and replaceable lenses.

4. Shop Welding

- Why Less Common: Auto-darkening helmets are usually preferred for high productivity.

- Possible Use: Still useful for overhead or confined welds.

Buying Guide: What to Look for When Purchasing a Leather Welding Helmet?

If you’re planning to invest in a leather welding helmet, keep these factors in mind:

1. Price Range

- Budget models: $40-$80 – Usually simple, single-layer leather hoods.

- Mid-range: $80-$150 – Better stitching, reinforced lenses, adjustable headgear.

- Premium/custom models: $150-$300+ – Handmade, highly durable, often custom-fitted.

2. Lens Compatibility

- Ensure the hood supports standard size welding lenses (usually 2″x4.24″).

- Look for flip-up lens options if you grind often.

3. Leather Quality

- Cowhide – Most common, strong, and durable.

- Split leather – More flexible but can wear out faster.

- Treated leather – Adds flame and spark resistance.

4. Comfort Features

- Adjustable straps.

- Lightweight stitching.

- Ventilation options.

5. Work Environment Suitability

- Field welding & pipefitting – Full leather hoods with side shields.

- Shop work – Hybrid models with leather and rigid combinations.

- High-heat jobs – Thick cowhide with reinforced stitching.

Real-World Welder Experiences with Leather Welding Helmets

Hearing from real welders can help put theory into perspective. Here are common insights from professionals:

Positive Feedback

- “Nothing beats a leather hood for pipe welding.” – Many welders swear by the flexibility.

- “My leather helmet has lasted 7 years.” – Durability is often highlighted.

- “So much lighter than my auto-darkening helmet.” – Reduced neck fatigue is a huge benefit.

Negative Feedback

- “Gets hot in summer.” – Lack of ventilation can be uncomfortable in warm climates.

- “Wish it had auto-darkening.” – Fixed shade lenses can be limiting for frequent tack welds.

- “Harder to find in stores.” – Availability is lower compared to mainstream helmets.

Mixed Opinion

Some welders keep both a leather helmet and an auto-darkening one. They switch depending on the job-using leather hoods for pipe and fieldwork, and auto-darkening helmets for shop fabrication.

Leather Welding Helmet vs Other Specialty Helmets

It’s worth comparing leather hoods to other niche helmets:

- Pancake Welding Hoods – Best for outdoor pipe welding; usually lightweight fiberglass with a side shield. Leather hoods are more flexible but heavier.

- Sugar Scoop Welding Hoods – Offer extra neck protection; often rigid but can be paired with leather flaps.

- Hard Hat Welding Helmets – Provide impact protection, while leather hoods don’t.

This makes leather helmets ideal for heat/spark resistance and flexibility, but not for impact-heavy environments.

The Future of Leather Welding Helmets

As welding PPE evolves, will leather helmets disappear? Unlikely. While auto-darkening helmets dominate the market, leather hoods remain relevant because:

- Pipe welding and fieldwork still demand flexibility.

- Many seasoned welders prefer them for comfort and tradition.

- Custom shops keep the demand alive by handmaking quality models.

Interestingly, some manufacturers are experimenting with auto-darkening lenses inside leather hoods, combining old-school comfort with modern convenience.

Conclusion: Should You Choose a Leather Welding Helmet?

A leather welding helmet may not be the best choice for everyone, but for the right welder, it’s a game-changer. Let’s summarize:

Choose a Leather Welding Helmet if:

- You’re a pipe welder, boilermaker, or field welder.

- You work in tight or awkward positions.

- You value lightweight comfort over technology.

- You want long-lasting, traditional protection.

Skip a Leather Welding Helmet if:

- You need auto-darkening convenience.

- You weld mostly in a shop or fabrication environment.

- You need impact protection beyond sparks and spatter.

Ultimately, the decision comes down to job type, comfort, and personal preference. Many professionals own both a leather hood and a modern helmet, giving them the flexibility to switch depending on the task.

For welders who embrace tradition, durability, and flexibility, a leather welding helmet remains an iconic piece of gear – a true symbol of craftsmanship in the welding trade.