Now Reading: Hard Hat Welding Hood: A Complete Guide to Welders

-

01

Hard Hat Welding Hood: A Complete Guide to Welders

Hard Hat Welding Hood: A Complete Guide to Welders

Welders face a unique blend of risks ranging from searing heat and blinding light to falling debris and dangerous sparks especially while working in hazardous industrial environments. While standard welding helmets are designed to protect the eyes from intense arc light and protect face from flying debris, they often leave the head vulnerable to other types of impacts. That’s when a hard hat welding hood really comes in handy. It is a hybrid piece of personal protective equipment (PPE) that combines the comprehensive protection of a hard hat with the advanced shielding capabilities of a welding hood.

Welding hoods compatible with hard hats or hard hat welding hoods are becoming increasingly popular as industries push for more efficient and safer workspaces. They are no longer niche tools but essential safety gear in construction, shipyards, heavy manufacturing, oil and gas sectors, nd other high-risk environments.

This guide will walk you through everything you need to know about hard hat welding helmets—how they’re built, how they work, top-rated options available, and tips for picking the one that fits your work style best.

What is a Hard Hat Welding Hood?

A hard hat welding hood or a hard hat welding helmet is a specialized type of welding helmet or face shield that is either mounted onto or integrated with a hard hat. These designs allow welders to benefit from:

- Falling or flying objects on head.

- Protection of eye and face from sparks, UV radiation, and infrared radiation.

- Improved comfort and adaptability in confined or elevated workspaces.

You’ll generally find two distinct structural designs for these helmets. They are:

- Hard Hat compatible Welding Hoods- These are separate hoods designed to be mounted onto regular hard hats using adapters or straps.

- Hard Hat integrated Welding Hoods- These are built into or permanently affixed to the hard hat, creating a seamless unit.

Both serve similar protective purposes but differ in flexibility, adjustability, and user preferences.

Why use a Hard Hat Welding Helmet instead of a Traditional Welding Helmets?

In controlled indoor environments, the traditional welding helmet is more than sufficient. However, when working in unpredictable or multidisciplinary settings, a hard hat welding hood offers multiple advantages like:

1. Dual Protection

Unlike regular welding helmets, a hard hat welding hood provides both:

- Impact protection from falling tools, steel parts, debris.

- Thermal and radiation protection from arc flash and sparks.

2. OSHA Compliance

In many industries, Occupational Safety and Health Administration (OSHA) standards require the use of head protection in active work zones. A hard hat welding hood helps professionals comply with these safety protocols without switching between helmets and hoods.

3. Productivity Gains

Manually switching between a hard hat and welding helmet not only reduces efficiency but also raises the risk of operational errors. An integrated solution ensures the welder is always protected, leading to fewer interruptions and increased productivity.

4. Better fit in tight workspaces

When working in tight or overhead positions such as in pipeline welding, ship hulls, or structural steel framing, a hard hat welding hood is often easier to maneuver compared to bulky standalone traditional welding helmets.

Breakdown of Hard Hat Welding Hood Components

Let’s break down their main components to fully appreciate the benefits of these hybrid welding hoods:

1. Hard Hat Shell

Most hard hats are made from tough plastics like HDPE or polycarbonate, which are known for being strong and good at absorbing impact. It is shaped to deflect falling debris and withstand blunt force impacts.

2. Welding hood assembly

This includes:

- Lens Housing: where the auto-darkening or passive lens is held.

- Lens filters: Lens options include both standard fixed shades—such as #10—and modern auto-darkening filters (ADF).

- Flip-up Shields: Some models offer a flip-up mechanism so you can lift the lens to inspect your work without removing the entire unit.

3. Mounting System

Depending on the model, mounting may involve:

- Snap-on adapters or brackets.

- Integrating mounting slots.

- Built-in suspension systems for customized head fitting and better comfort.

4. Headgear Suspension

Many premium welding hoods offer padded, multi-point suspension systems that reduce neck fatigue and allow size adjustments.

Types of Hard Hat Welding Hoods

Not all welding hoods are built the same—each type serves a unique purpose. Below is a quick overview of the most commonly used ones.

1. Passive Lens Hard Hat Hoods

These hoods use a fixed dark lens, usually shades in between 10-14. They are durable, inexpensive, and ideal for high-heat, repetitive tasks like stick welding. However, they require the welder to nod the hood down before striking the arc, which can be cumbersome.

2. Auto-darkening Filter (ADF) Hard Hat Hoods

ADF hard hat hoods are more technologically advanced as the lens in them automatically adjusts its darkness level when the arc is struck. Benefits include:

- faster workflow

- less strain on the neck

- improved weld accuracy

Some top models also offer variable shades (typically #5-#13) and even color enhancement technology.

3. Flip-up Welding Hoods with Hard Hat

These type of hoods feature a flip-up welding lens over a clear grinding shield, allowing welders to switch between welding and other tasks without removing their hood. It works well for various tasks such as grinding, fitting, and general fabrication.

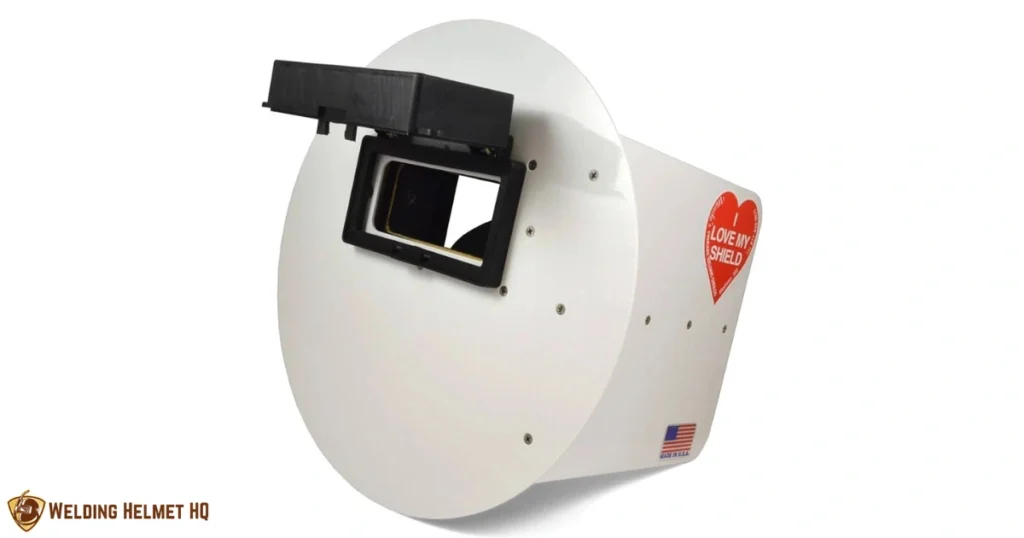

4. Pancake Welding Hoods with Hard Hat compatibility

Pancake hoods are known for their side-shielding design and are often used in pipeline welding. Some manufacturers now also offer pancake-style welding hoods with attachments that can be mounted onto hard hats, providing protection without sacrificing maneuverability.

5. Full-face Respirator Welding Hoods

Some hard hat welding helmets also come with integrated PAPR systems (Powered Air Purifying Respirators) for hazardous environments with toxic fumes. These hoods combine welding protection with clean airflow, keeping the welder safe from inhaling fumes and particles.

When is a Hard Hat Welding Hood absolutely necessary?

While any welder benefits from integrated protection, there are some scenarios where a hard hat welding hood is essential:

- Construction Sites: where falling debris, beams, or tools pose a constant threat.

- Shipyards and Offshore Platforms: harsh weather and multi-layered teams demand all-around protection.

- Oil and Gas Fields: requires protection for your head, eyes, and breathing all at once.

- Welding at heights: where steadiness and full safety compliance can’t be compromised.

- Pipeline Welding: often done in open environments where both arc flash and head injuries are real dangers.

Top features to look for in a Hard Hat Welding Hood

Choosing the right hard hat welding hood is not just about brand recognition, it is about ensuring the gear meets your unique work demands. Things to consider before you buy:

1. Compatibility

Always check whether the welding hood is directly integrated with a hard hat or compatible via adapters.

Some hoods only work with specific brands or models of hard hats. If you’re already using a particular hard hat (like MSA, 3M, or Bullard), confirm compatibility.

2. Lens Type: Passive vs Auto-darkening

Passive Lens

Passive lens are simple, durable, and budget-friendly. They have a fixed shade (usually #10) and are great for stick welding.

Auto-darkening Lens (ADF)

Auto-darkening lens are good for TIG, MIG, and multi-process welding. They reduces neck fatigue and improve accuracy. They can have a variable shade from 5-13.

3. Optical Clarity Rating

Check for an EN379 rating—this standard scores the helmet’s performance in four areas: Light Diffusion, Luminous Transmittance, Angle Dependence, and Uniformity. The best clarity score is 1/1/1/1.

4. Viewing Area

Larger viewing lenses let you see more of your work area without having to move your head all the time. Most professional hoods offer 3.74 inch x 3.34 inch or wider views.

5. Weight and Ergonomics

Welding is physically demanding. Therefore, a heavy or poorly balanced hood can lead to neck fatigue, reduced mobility, or lower precision.

Always opt for hoods that have multi-point adjustable suspension systems and breathable padding.

6. Flip-up or Fixed Lens Design

Flip-up designs are ideal for welders who also grind or inspect work regularly.

Fixed-lens designed hoods are simpler but require removing the hood to switch tasks.

7. Ventilation and Respiratory Options

If your welding work involves toxic fumes or poor ventilation. Then, consider a hard hat welding hood with PAPR system or one with the face-seal and air-intake channels.

8. Safety Certifications

Make sure your hood meets:

- ANSI Z87.1+ (eye/face protection)

- ANSI Z89.1 (head protection for the hard hat)

- CSA standards (if you’re in Canada)

- EN379 (for European standards)

9. Accessories and Spare Parts availability

Choose brands that offer replacement lenses, suspension parts, sweatbands, batteries or chargers for auto-darkening filter hoods. As availability ensures long-term usability and lower cost of ownership.

Comparison Table

| Feature | Basic Passive Hood | ADF Compatible Hood | Full-integrated PAPR Hood |

|---|---|---|---|

| Lens type | Fixed | Auto-darkening | Auto-darkening |

| Hard Hat Integration | Adapter | Adapter or built-in | Built-in |

| Comfort | Moderate | High | Very High |

| Price Range | $30-$100 | $150-$400 | $500-$1200+ |

| Ideal For | Stick and Pipeline Welding | Multi-process welders | Industrial, toxic environments |

How to Maintain and Care for Your Hard Hat Welding Hood?

Investing in a quality hard hat welding hood is only half the battle, maintaining it is also as critical. Proper maintenance and care not only extends the life of the hood but also ensures you stay protected every time you use it while welding.

1. Regular Cleaning

- Outer Shell: Regularly, wipe the hard hat shell and hood exterior with a soft cloth and mild soap solution. Stay away from strong cleaners that might damage the lens or plastic parts.

- Lens: Clean the lens gently using a soft microfiber cloth and a cleaner designed for optical surfaces. Never use abrasive pads as auto-darkening lenses are sensitive to scratches.

- Suspension System: Remove sweatbands and padding weekly and wash them with warm water. Replace when worn or stained.

- Ventilation Ports (if applicable): Especially in PAPR-integrated systems, clear any debris or dust build-up that can affect airflow.

2. Inspect before each use

Perform daily visual inspection to check:

- any breaks or cracks in the hard hat shell or welding hood.

- any damage to suspension straps or ratchets.

- any burn marks near the lens area.

- functionality of the auto-darkening feature.

- Inspect the condition of the battery or solar unit in ADF helmets regularly.

3. Replace parts promptly

Don’t wait for critical components to fail during use:

- Lenses: Swap out cracked, foggy, or scratched lenses.

- Headgear: Replace when it no longer tightens securely.

- Sweatbands: Replace sweatband every month as a dirty sweatband can harbor bacteria.

- PAPR filters: Replace filters as per manufacturer’s recommendation (often every 2-4 weeks depending on the usage or exposure).

4. Storage Tips

Store the welding hood in a shaded, moisture-free area to prevent damage. Also use a helmet bad or hard case for keeping it, especially when travelling. Don’t stack heavy objects on your hood, as it can bend or misshape it over time.

Common mistakes to avoid

Even seasoned welders can unknowingly put themselves at risk by making simple mistakes. These are some of the main ones you should keep an eye on:

Mistake 1: Using Incompatible Hard Hat and Hood

Not all hoods are universally compatible. Using an ill-fitting adapter or forcing a hood onto a non-compatible hard hat can weaken the locking mechanism, cause unexpected dislodging and can also compromise safety certifications. Therefore, always refer to the compatibility charts provided by the manufacturers.

Mistake 2: Ignoring Safety Ratings

Some welders opt for a cheaper, uncertified hood or equipment that lacks ANSI/CSA approval. While it may work temporarily, it puts your vision, lungs, and head at serious risk.

Mistake 3: Exposing the ADF lens to direct sunlight for too long

Exposing your auto-darkening filter lens to UV rays when not in use can cause sensor malfunction, permanent discoloration, and false shade activation. That’s why it is best to store your hood safely when you’re not using it.

Mistake 4: Welding with a dirty or fogged lens

A dirty lens can distort your view, leading to inaccurate welds, increased eye strain, and missed hazards. That’s why always clean your lens before every shift.

Tips for maximizing performance and comfort

After working in welding industry since a decade as a professional welder. Here are some of the pro tips to maximize your performance and comfort while using hard hat welding hood:

1. Customize the fit

A poorly fitted hood can lead to migraines and neck pain. So, it is really important to adjust suspension straps, chin rests, and tilt angles until you find a natural and balanced fit. Fir long shifts, invest in gel-cushioned sweatbands for added comfort.

2. Upgrade the lens (if possible)

Most high-end hoods allow lens replacement. So, upgrading to a newer-generation auto-darkening filter lens with True Color Technology can drastically improve visibility and reduce eye fatigue.

3. Use anti-fog inserts or sprays

Use anti-fog lens wipes or inserts to maintain clarity as fogging is a common issue, especially in hot or humid environments.

4. Train for low-light and tight spaces

Get used to switching to grind mode or flipping your helmet in tight spaces so you’re not fumbling mid-task. Familiarity with your gear improves efficiency and safety.

5. Create a Maintenance log

Especially in team environments, track usage, battery replacement, lens swaps, and filter changes using a simple maintenance checklist. This will ensure consistent protection and equipment longevity.

Final Verdict: Is a Hard Hat Welding Hood worth it?

Absolutely.

In environments, where safety, productivity, and compliance are top priorities, a hard hat welding hood is a necessity, not a luxury. Whether you’re welding beams or high-rise, laying pipe in oil fields, or grinding hulls in shipyard, combining head and face protection in a single unit enhances your confidence and capability.

Who should use a Hard Hat Welding Hood?

Anyone from structural welders to pipeline welders, construction and fabrication professionals to shipyard workers, or even industrial welders in confined spaces can and should use a hard hat welding hood for safety of their head as well as of face.

Conclusion

The hard hat welding hood is not just another PPE item but it is an essential component of modern welding safety strategy. By understanding the types, choosing the right features, and maintaining your hood with care, you’re investing in both your protection and your performance.

In a field, where visibility, precision, and safety mean everything, the right hood can make the difference.

Frequently Asked Questions (FAQs)

Q1: Can I use any welding hood with a hard hat?

No, only certain welding hoods are designed or can be used with a hard hat. So, always check the product specifications and adapter compatibility list form the manufacturer.

Q2: What’s better: A flip-up hood or a fixed lens hood?

It depends on your workflow. Flip-up hoods are better for multi-process jobs like welding and grinding. While, fixed lens hoods are more compact and lighter for jobs like pipeline welding.

Q3: Is auto-darkening worth the extra money?

Yes, for most professional applications. As it improves efficiency, reduces neck strain, and offers better visibility. However, for high-heat or outdoor jobs where simplicity is preferred, a passive lens stills works well.

Q4: How often should I replace the welding lens?

Auto-darkening filter (ADF) lenses usually last 2-5 years with proper care. On the other hand, passive lenses may last longer but should be replaced when scratched or clouded.

Q5: Can I weld overhead with a hard hat welding hood?

Yes, especially if the hood is well-balanced and the shell meets ANSI Z89.1 Type 1 standards.. Also add a flame-resistant neck coverings if needed and ensure a snug fit.