Now Reading: Passive Welding Helmet: A Complete Guide for Beginners and Professionals

-

01

Passive Welding Helmet: A Complete Guide for Beginners and Professionals

Passive Welding Helmet: A Complete Guide for Beginners and Professionals

Welding requires a high level of accuracy, a strong focus on safety, and the ability to adapt to different conditions. A welding helmet is the most essential piece of protective equipment, playing a central role in every successful weld. While modern welding helmets are packed with auto-darkening sensors and digital interfaces, there is one type of helmet that continues to hold its ground among professionals and hobbyists alike the passive welding helmet.

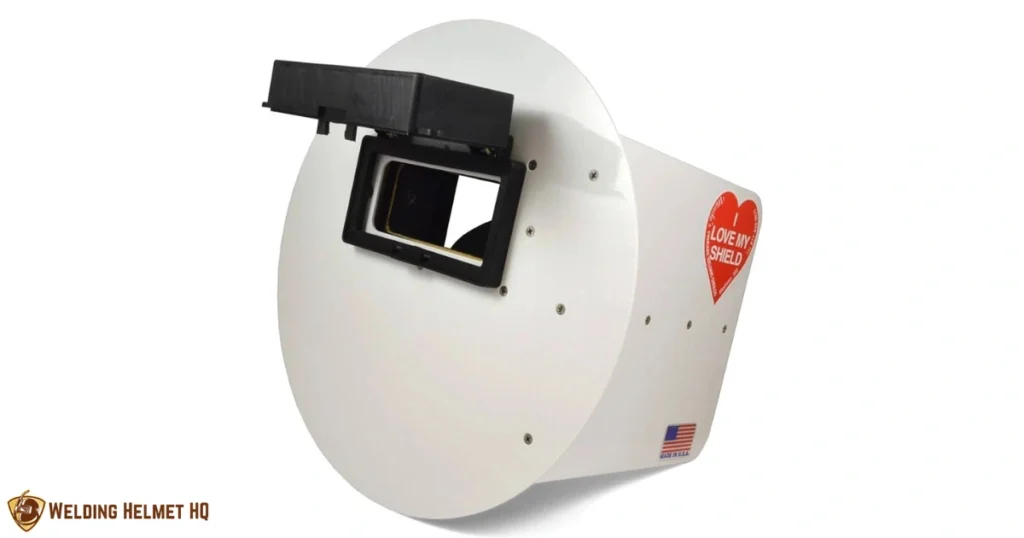

A passive welding helmet is the traditional type of welding helmet that uses a fixed shade lens, usually shade #10, to protect the eyes and face from UV and IR radiation.

Unlike auto-darkening helmets that adjust themselves when the arc strikes, passive helmets keep things old-school. You’ll need to manually lift the helmet to take a look at your work or to position your weld — and lower it again right before you start welding.

Though considered “old-school”, passive helmets are far from obsolete. In fact, they offer several distinct advantages that make them a preferred choice in specific situations, especially for experienced welders.

What is a Passive Welding Helmet?

Passive welding helmets are specifically designed to guard against:

- Bright light and arc flash

- Sparks and spatter

- UV and IR radiations

- Debris and physical impact.

These helmets use a fixed-shade lens, usually shade #10 or darker, which doesn’t change in brightness. This means the lens remains dark all the times, even when the welder is not actively welding. Welders have to raise the helmet by hand whenever they want to see the workpiece. And, when ready to strike the arc, they lower it quickly into position.

Key Components of Passive Welding Helmets

- Fixed-Shade lens (typically shade #10)

- Durable Shell often made of polyamide or fiberglass

- Headgear/straps for adjustability and comfort

- Flip-front or full-face design

- Protective outer and inner cover lenses (replaceable)

Passive vs Auto-darkening Welding Helmets: A Quick Comparison

Let’s quickly compare passive welding helmets with auto-darkening welding helmets before going deep into its specifics.

| Feature | Passive Welding Helmet | Auto-darkening Welding Helmet |

|---|---|---|

| Lens Type | Fixed Shade (#10 or more) | Adjustable shade (8-13, automatic) |

| Visibility before Arc | Must lift helmet | Clear or lightly tinted before arc |

| Response Time | Manual Adjustment | Instant (1/20,000s or faster) |

| Battery/Electronics | No electronics | Uses batteries and sensors |

| Cost | Less expensive | More expensive |

| Durability | High (fewer moving parts) | Moderate (sensitive electronics) |

| Learning Curve | Steeper | Easier for beginners |

As we can see in above table that passive welding helmets offer simplicity and durability whereas auto-darkening welding helmets emphasize convenience and technology.

Advantages of using a Passive Welding Helmet

Despite the popularity of auto-darkening welding helmets, passive welding helmets offer several advantages that keep them in demand:

1. Durability and Reliability

Passive welding helmets are build to last. Since they contain no electronic parts, they are less prone to any malfunction or sensor failure. This makes them ideal for harsh work environments like shipyards, construction sites, and fabrication shops.

2. Cost-Effective

Passive helmets are significantly cheaper than auto-darkening welding helmets which makes them a great option for beginners learning the welding craft, welders on a budget or backup helmets in a professional welding shop.

3. Lightweight Construction

Most passive welding helmets use lightweight materials like fiberglass or thermoplastic, making them easier to wear for long hours — ideal for welders who spend hours on repetitive tasks.

4. No Dependency on Power

You never have to worry about a dead battery mid-job as passive helmets don’t rely on batteries or solar panels. So, there’s no downtime, just pure mechanical function.

5. Better for some Precision Tasks

Many experienced welders prefer passive welding helmets for Stick(SMAW) welding and Flux-Cored Welding because of the clarity and reliability of a fixed shade. They can focus on the puddle and arc without worrying about the delay times or flickering sensors.

Challenges and Drawbacks of Passive Welding Helmets

Despite so many strengths, passive welding helmets aren’t perfect. Here are some of the common challenges face by welders when using these helmets:

1. Manual Operation

The biggest drawback of passive helmets are that you need to manually flip the helmet down before striking the arc. This can be tiring and inconvenient, especially for beginners.

2. Limited Visibility

Passive helmets keeps the lens dark all the time, so it’s tough to see your work clearly before you strike the arc. This can cause misaligned starts, especially for beginners.

3. Steeper Learning Curve

To use effectively, passive welding helmets require a certain level of skill and timing. That’s why beginners or new welders often struggle with nodding the helmet down while simultaneously striking the arc.

4. Limited Shade Flexibility

You’re locked into one level of protection with a fixed-shade lens. This may not be ideal for various welding applications where different arc intensities require different shade levels.

Who should use a Passive Welding Helmet?

Passive welding helmets are best suited for:

- Skilled Welders who have developed a rhythm and muscle for lowering their helmets.

- Budget-conscious users who are looking for a basic yet reliable welding helmet.

- Heavy-duty environments where durability and simplicity are more important than automation.

- Schools and training institutes that require cost-effective safety equipment for a large number of students.

These helmets are also great as backup helmets or for tasks where quick, repetitive welds are performed, and there is no need to switch between different shades.

What makes a good Passive Welding Helmet?

Here’s a top features to look for if you’re considering buying a passive welding helmet:

1. Lens Quality

Ensure that the lens is made from high-impact-resistant materials and provides 100% UV/IR protection.

2. Helmet Shell Durability

Choose an outer shell that is durable yet light enough for comfortable use. Materials like thermoplastic and fiberglass are popular because they offer durability without adding any unnecessary weight, making the helmet comfortable to wear.

3. Comfortable Headgear

The soft padding and adjustable straps ensure a snug fit, making it comfortable to wear throughout extended welding tasks.

4. Replaceable Lens Covers

Being able to easily replace both inner and outer cover lenses extends the life of your helmet.

5. Flip-front Option

Some passive welding helmets come with a flip-front lens that allow to quickly switch from welding to grinding mode without removing the helmet.

Best Applications for Passive Welding Helmets

While passive welding helmets can be used across all welding processes, they are particularly well-suited to certain types of welding:

1. Shielded Metal Arc Welding (SMAW)

Because of the constant and instant arc, passive helmets are ideal for stick welding. And, there’s no need for variable shading as shade #10 works well with stick electrodes.

2. Flux-Cored Arc Welding (FCAW)

With flux-cored welding processes producing a high level of spatter and arc intensity, passive helmets offer excellent protection and consistency.

3. Grinding and Cutting Tasks

Flip-front passive welding helmets are a great choice for welders who need to switch between welding and grinding or torch cutting quickly without removing the entire helmet.

4. High-Volume, Repetitive Welding

In manufacturing environments where the same welds are performed repetitively, a passive welding helmet eliminates the need to constantly adjust settings which makes it efficient and reliable.

Passive Helmets in Educational Settings

Passive helmets are commonly used in trade schools and vocational institutes because:

- They are cost-effective for equipping large classes.

- They teach students how to time the arc and helmet flip.

- They are durable and easy to maintain.

Many instructors also believe that learning with a passive helmet helps students become more disciplined and precise in their welding techniques.

How to choose the right Passive Welding Helmet? Buying Guide

Several factors should be taken into consideration to ensure both safety and usability when purchasing or buying a passive welding helmet:

1. Shade Rating

Most passive welding helmets come with a fixed shade #10 lens, but depending on the process and amperage, you may require different shades:

- Shade #10: This shade is often used when you’re doing Stick welding or some MIG welding tasks.

- Shade #11 to #13: Use these shades when doing high-amp welding jobs like MIG or flux-core welding to protect your eyes better.

- Shade #9: Ideal for lower-amperage TIG.

Make sure that the helmet supports lens replacement in case you want to upgrade the shade later.

2. Lens Clarity and Viewing Area

Not all passive welding helmets have the same optical quality. So, look for:

- ANSI Z87.1 or CSA Z94.3 compliance

- Optical Clarity Ratings (1/1/1/1 being best)

- Sufficient viewing window (standard is about 4.5 inch x 5.25 inch)

3. Material and Build Quality

The shell should be flame-resistant and heat-tolerant, lightweight for comfort, and tough enough to withstand drops and impacts.

Thermoplastic is lighter but slightly less durable than fiberglass which is heavier but offers higher resistance.

4. Fit and Comfort

Comfortable headgear is essential. So, look for adjustable ratchets, padded sweatbands, and balanced weight distribution. If your welding helmet doesn’t fit right, it can strain your neck and slow you down while working.

5. Optional Features

- Flip-front lenses: They allow welders to easily switch between active welding and inspecting their weld without removing the helmet.

- Hard-hat Adapters: It is necessary for industrial job sites with head protection requirements.

- Ventilation Slots: Some helmets have small vents built in to help cut down on sweat and keep the lens from fogging up.

Maintenance Tips for Passive Welding Helmets

Taking good care of your passive welding helmet ensures long life and clear vision:

- Regularly clean the lens covers both inside and out with a non-abrasive cloth.

- Scratched or foggy cover lenses should be replaced promptly, as poor visibility can lead to errors and eye strain.

- Check the straps often—if they’re worn out or don’t hold the helmet securely, it’s time to swap them out.

- Always keep your helmet in a moisture-free, dust-free environment to avoid dust buildup, corrosion or cracking.

Are Passive Helmets Obsolete in 2025?

Absolutely not. Despite the rise of advanced auto-darkening models, passive helmets are still in demand, especially by those who work in challenging environments, want a backup or secondary helmet, welding specific processes like stick or flux-core, and value simplicity and toughness over convenience.

These helmets might not be the flashiest things or tools in your kit but they offer a level of consistency, predictability, and toughness that tech-heavy helmets sometimes lack.

How to properly use a Passive Welding Helmet?

Passive welding helmets require manual coordination between your hands and jead. Here are some of the tips to ensure you use them safely and effectively:

1. Position the Helmet correctly

Before you start welding, make sure the helmet is properly secured on your head using the adjustable straps, positioned so the lens aligns with your natural line of sight, and held in the lifted position until it’s time to begin welding.

2. Learn the “nod-down” technique

To lower the helmet right before striking the arc, practice smoothly “nodding” your head forward to drop the helmet in place. Also ensure that the helmet doesn’t move too quickly causing disorientation or too slowly causing you to miss the starting point. This motion becomes easier with repetition and builds muscle memory, essential for consistent weld starts.

3. Set Up Good Lighting

As passive helmet’s lenses stay dark all the time, ensure that you have ample workspace lighting before you flip the helmet down and prepare the torch and electrode precisely beforehand.

4. Keep Spare Lenses Ready

Keep a few spare lenses of different shades for various welding processes as passive lenses are not adjustable. It is also a good practice to carry replacement cover lenses, as scratches can quickly impair visibility.

Common Mistakes to Avoid

Using a passive welding helmet incorrectly can not only reduce the weld quality but also risk injury. So, avoid these common mistakes:

1. Not Checking Lens Clarity

Damaged or poor installation of the lens—such as scratches, cloudiness, or misalignment—can strain your eyes and make it harder to manage the weld puddle with precision.

2. Forgetting to replace Worn Headgear

If the straps are worn out or too loose, your helmet might slip while you’re using it—which can be risky when flipping it up or down.

3. Using the wrong shade

A lens that is too light won’t block enough UV and IR radiation, putting your eyes at risk. While using too dark, and you’ll have poor visibility, leading to errors.

4. Not practicing Helmet Timing

Beginners often struggle with simultaneously lowering the helmet and striking the arc. Practice on strap metal to get this coordination right before moving to important projects.

When to Choose a Passive Welding Helmet over an Auto-darkening Helmet?

It’s tempting to jump straight into modern gears, but passive welding helmets still outperform auto-darkening helmets in several use cases:

| Use Case | Why Passive Helmets are better |

|---|---|

| Harsh Outdoor Environments | No electronic components—less risk of failure from dust, moisture or weather |

| Budget projects or workshops | Lower upfront cost and maintenance |

| Heavy-duty fabrication | Durable, heat-resistant shell |

| Long welding hours | Lighter weight, reduces fatigue |

| Teaching and training | Encourages better form and timing for students |

| Backup helmet needed | Reliable, no batteries or sensors to fail |

Passive Welding Helmets for specific users

For Beginners:

While they’re a bit harder to master, passive welding helmets help beginners develop timing and awareness. Learning to weld without relying on automation improves skill and understanding of the process.

For Professionals:

Experienced welders who don’t mind flipping their helmet down before striking an arc often prefer the clarity and simplicity of passive lenses.

For Industrial Welders:

Many industrial and job-site regulations still require passive or non-electric helmets in hazardous environments. The lack of electronics makes these helmets immune to electromagnetic interference or failure due to heat exposure.

Future of Passive Welding Helmets: Are they going away?

Far from it. While technology is pushing auto-darkening welding helmets forward but there is a growing trend of retro in tool craftsmanship, including welding. So, passive welding helmets are being redesigned with better ergonomics and materials, offering hybrid options like flip-front passive lenses in modern shells, and being marked as the “purist’s choice” for traditional welders.

Just like manual transmission in sport cars, passive welding helmets offer direct control, pure experience, and lower failure rates which many welder still highly value.

Final Thoughts: Should you buy a Passive Welding Helmet?

If you’re looking for a budget-friendly, durable helmet with no batteries or electronics and a long-term reliability. In that case, opting for a passive welding helmet would be a smart and worthwhile choice.

It might take time to get used to the rhythm of nodding the helmet into place, but once mastered, the simplicity and consistency of a passive welding helmet often outperform newer options for specific jobs.

Whether you’re a beginner learning the ropes or a seasoned professional in need of a reliable backup, passive welding helmets still hold their place in the welding world as a tough, affordable, and time-tested gear.