Now Reading: How to Use a Hard Hat Adapter for Welding Helmet? Full Installation & Safety Guide

-

01

How to Use a Hard Hat Adapter for Welding Helmet? Full Installation & Safety Guide

How to Use a Hard Hat Adapter for Welding Helmet? Full Installation & Safety Guide

Welders are exposed to extreme temperatures, intense light, and flying sparks during welding—each posing serious risks. That’s why Personal protective equipment (PPE) is crucial not just for safety compliance but for survival. Welding helmets and hard hats are two of the most essential safety items in a welder’s protective gear.

However, in industrial environments like construction sites, shipyards, and large-scale fabrication shops, you often need both simultaneously. In such cases, using an adapter to connect your welding helmet to a hard hat is not just useful—it’s essential.

Whether you’re a seasoned welder or just getting started, this article will help you make an informed decision about incorporating a hard hat adapter into your daily workflow.

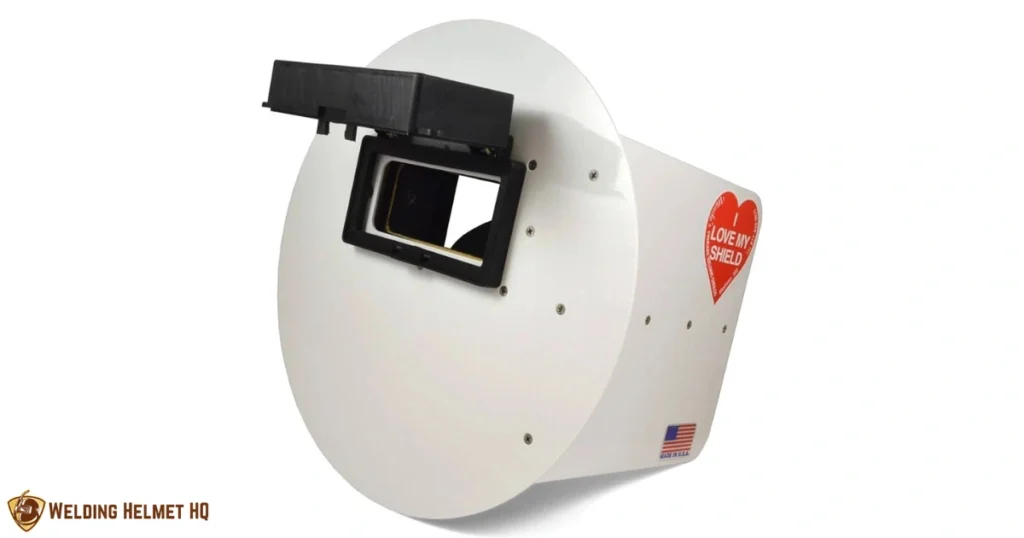

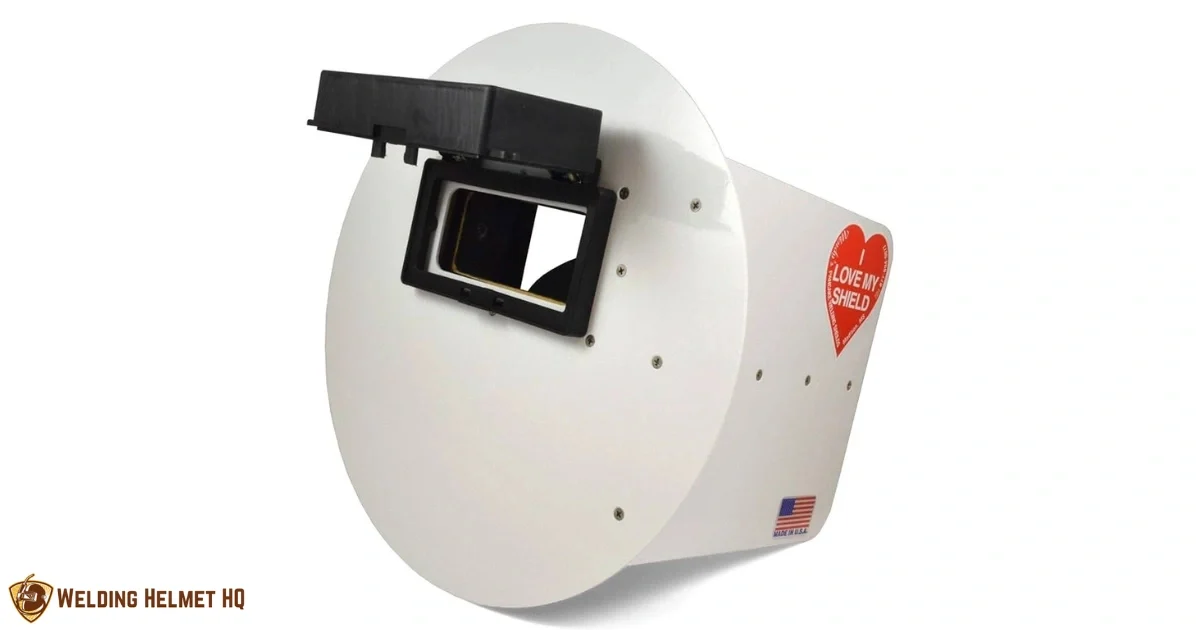

What is a Hard Hat Adapter for Welding Helmet?

A hard hat adapter helps connect your welding helmet and hard hat so you can wear both together easily. Welders can seamlessly integrate their safety gear rather than juggling two separate pieces of headgear.

In simple words, it acts as a bridge between the two safety components, ensuring that the helmet fits snugly and functions correctly while being supported by the hard hat.

Why combine a Welding Helmet with a Hard Hat?

Welding helmets serve as essential protection against high temperatures, harmful rays, spark bursts, and floating particles that pose risks to your face and eyes. On the other hand, hard hats are designed to shield your head from falling objects, sharp edges, and impact-related injuries.

If you’re welding in environments where both falling debris and high-risk welding hazards are present. Then, you simply cannot sacrifice one for the other. A hard hat adapter makes it possible to wear both comfortably and securely.

When do you need a Hard Hat Adapter?

Here are a few scenarios where using a hard hat adapter for welding helmet is practically non-negotiable:

1. Construction Sites

- Multiple trades working simultaneously like welding, plumbing, electrical, carpentry.

- Working overhead can be risky due to falling gear or debris.

2. Oil & Gas Industry

- Structural welders need hard hats to protect from falling objects and welding helmets for accurate welds.

3. Shipbuilding Yards

- Overhead welding is often done in cramped areas where multiple workers are present. Dual protection is essential.

4. Mining and Tunneling

- Tough working conditions and limited visibility make it crucial to protect both the head and face.

Challenges without a Proper Adapter

Trying to manually wear a welding helmet over a hard hat or vice versa can be awkward, dangerous, and non-compliant. Here are some of the issues faced when not using a proper adapter:

- Unstable Fit: Welding helmet slides or shifts when trying to wear over a hard hat.

- Reduced Visibility: When the visor isn’t properly angled, it can block or distort your line of sight.

- Discomfort: Pressure points on the head and neck due to overlapping gear.

- Exhaustion: Constantly readjusting the gear can wear you down physically and mentally, leading to overall fatigue.

- Safety Violations: Failing to wear the hard hat correctly can result in citations or worse, injuries.

Different Kinds of Adapters to Attach your Welding Helmet to a Hard Hat

Hard hat adapters are not universal. Several designs exist to fit different welding helmets and hard hat models. Here’s a breakdown of common types:

1. Slotted Adapters

Most hard hats have standard side slots where these adapters can be easily attached. Once slotted in, the welding helmet can be mounted and adjusted for angle and tension.

Pros:

- Easy to attach and remove.

- Compatible with most standard hard hats.

- Lightweight and compact.

Cons:

- May not support heavier helmets well.

- Limited adjustability on some models.

2. Cap-style Adapters

These are designed to wrap around the hard hat and clip on using clamps or secure bands. This style offers more flexibility in mounting but can be bulkier.

Pros:

- Works with non-slotted hard hats.

- Better weight distribution for heavier helmets.

Cons:

- Slightly more complex to install.

- May interfere with earmuffs or headlamps.

3. Custom OEM Adapters

Some manufacturers like 3M, Jackson Safety, or Lincoln Electric make adapters that are designed specifically for their helmet and hard hat models.

Pros:

- Perfect fit and maximum compatibility.

- Often more durable and ergonomic.

Cons:

- Expensive.

- Limited to specific brands or models.

4. Magnetic or Quick-Release Systems

Some high-end adapters come with magnetic or snap-lock mechanisms that allow welders to detach their helmets quickly—great for multitasking welders.

Pros:

- Let’s you easily change between welding and grinding modes without any hassle.

- Minimal wear on helmet brackets.

Cons:

- Costly.

- Risk of dislodgement if magnets weaken.

Material and Build Considerations

A good hard hat adapter makes your helmet feel more comfortable and last longer. Keep the following in mind when choosing an adapter:

- Materials: Most are made from high-impact ABS plastic, fiberglass, or aluminum-reinforced nylon.

- Temperature Resistance: Good adapters withstand high-heat environments typical in welding operations.

- Adjustability: Look for adapters that allow angle and tension adjustment, especially if you use a flip-up helmet.

Brand Compatibility Overview

Use the chart below to match well-known hard hats with compatible welding helmets. And, whether they offer compatible adapters:

| Helmet Brand | Hard Hat Compatibility | Adapter Availability |

|---|---|---|

| Lincoln Electric | Slotted and cap-style | Yes (K3034-4 & others) |

| Miller Electric | Slotted only | Yes (MP-10 Series) |

| Jackson Safety | Universal | Yes (HSL 100 & HLX Series) |

| 3M Speedglass | OEM required | Yes (Adflo Systems) |

| Optrel | OEM or custom | Limited availability |

How to install a Hard Hat Adapter to your Welding Hood?

Installation varies based on the type of adapter and your specific helmet and hard hat model. Below is a step-by-step general guide for both slotted and cap-style hard hat adapters.

For Slotted Hard Hat Adapters:

These adapters are the simplest in design and among the most commonly used.

Inspect the Hard Hat Slots

- Ensure your hard hat has universal side slots (most type I and type II hard hats do).

- Check that the slots are clean and clear of any dust or debris before installing.

Attach Adapter Arms

- Slide the adapter arms into the helmet slots until they fit tightly.

- Apply steady pressure until it clicks into position, signaling a proper fit.

Secure the Welding Helmet

- Mount your welding helmet to the adapter using the provided knobs or pivot bolts.

- Modify the side knobs until the helmet lifts and lowers without resistance.

Final Fit Test

- Put on the hard hat, then pull the helmet down to cover your face.

- Gently move your head to check if the gear is secure.

For Cap-Style or Clamp-On Adapters:

These adapters offer more flexibility but can take a bit more time to install.

Wrap Adapter Frame around Hard Hat

- Place the adapter frame over the top of the hard hat, making sure it rests evenly in place.

Clamp and Tighten

- Secure the adapter onto the hard hat using side locks or clamps.

- Check that the frame doesn’t block or clash with other gear.

Attach and Align the Helmet

- Connect the helmet securely to the frame so it won’t shift while you weld.

- Adjust for both height and viewing angle.

Check Comfort and Balance

- Ensure that the weight of the helmet doesn’t cause the hard hat to shift as balance is the key.

Tips for using a Hard Hat Welding Helmet Adapter Effectively

Having a top-quality adapter is just one part of the equation, how you use and maintain it also impacts your safety, productivity, and comfort.

1. Check Fit Daily

Before each shift, ensure that the adapter is still securely attached and that no plastic parts have loosened or cracked. A daily safety check is crucial.

2. Adjust Tension Regularly

The flip-up feature of your helmet is only helpful if it stays in place. Adjust tension knobs as needed to prevent accidental slippage during work.

3. Avoid Over-Tightening

While secure attachment is important, over-tightening can crack plastic adapters or stress pivot points. Aim for a firm but flexible hold.

4. Combine with Face Shields or Earmuffs

You can find adapters that work well with other PPE, including earmuffs and visors. Make sure that your model supports such add-ons if your work demands them.

5. Store Properly

Make sure to put the helmet and hard hat away in a moisture-free, safe area after use. Avoid tossing it into lockers or tool bags without care as this can damage the alignment.

Advantages of using a Hard Hat Adapter

Integrated Safety

When welding, no need to remove your hard hat as it keeps you protected at all times.

Hands-free Operation

The adapter allows easy flipping up and down of the helmet, enabling faster task-switching.

Compliance with Regulations

With an integrate setup, adhering to both ANSI Z89.1 and OSHA 1910.135 safety standards is easier.

Better Productivity

Instead of stopping to reposition safety gear, workers cam focus on their welds.

Customizability

Many systems allow for additions like visors, earmuffs, and headlamps.

Drawbacks of using Hard Hat Adapter

These helmets are great, no doubt—but they do come with a few drawbacks.

Weight and Neck Strain

Adding a welding helmet to a hard hat increases total headgear weight which can strain the neck over long shifts.

Compatibility Issues

Not all helmets and hard hats are plug-and-play. Mismatched gear may require adapters or new purchases.

Cost

Quality adapters, especially OEM models, can be expensive. This is particularly true for proprietary systems.

Complex Adjustments

Fine-tuning multi-angle gear often requires patience to get the alignment perfect.

Maintenance and Care Tips

A hard hat adapter is a mechanical component subject to wear and tear, especially in harsh welding environments. Follow these steps to maintain your equipment at its best:

1. Clean Regularly

Use a damp cloth and gentle soap to clean both metal and plastic parts. Also avoid any harsh solvents that can degrade plastic brackets or damage rubber seals.

2. Inspect for Wear

Check for any cracks, warps, or weakened pivot points at least once a week. And, replace broken knobs or stripped adjustment gears immediately.

3. Lubricate Moving Parts

Apply a small amount of non-flammable silicon spray or dry graphite lubricant to pivot joints. Avoid using any il-based lubricants that can attract dust and grime.

4. Replace when Necessary

Replace adapter systems every 12-24 months depending on use, or sooner if damaged. Treat your adapter like a consumable and not a lifetime component.

How to choose the best Hard Hat Adapter?

Welding safety gear isn’t one-size-fits-all. The ideal adapter varies based on your helmet, job site, and how comfortable it feels.

Below are the main factors to look at before deciding:

1. Compatibility

Test if the adapter stays in place and works with both your helmet and hard hat. Use OEM adapter kits if available as they are built for perfect alignment and compliance.

2. Purpose of Work

Choose robust adapters like the Fibre-Metal 4178 that can handle heavier helmets for overhead welding. And for construction welding, opt for lightweight slotted adapters for easier portability.

3. Adjustability

Look for multi-angle pivot arms and tension control knobs to sine-tune your helmet’s flip-up movement. As welders with corrective lenses or magnifiers may need more range of motion.

4. Comfort and Ergonomics

Test how the helmet balance on your hard hat with the adapter installed as poor ergonomics can lead to neck fatigue or strain over long shifts.

5. Durability

Avoid cheap plastic models that wear down quickly under heat and impact. Choose metal or fiberglass-blend adapters if you’ll be working in areas with high heat.

Common Mistakes to Avoid

Even seasoned welders can fall into traps when dealing with the adapters. Watch out for these frequent errors when using a hard hat adapter:

Don’t mismatch brands

A Lincoln Welding Helmet on a 3M hard hat adapter? Probably won’t work. So, always check compatibility charts.

Don’t overtighten knobs

Never overtighten knobs as that can crack the adapter and reduce the lifespan. Tighten just enough to hold firm.

Don’t ignore worn-out parts

It is time to replace the pivot or the entire adapter, if the helmet droops or won’t stay up.

Don’t assume “one-size-fits-all”

Some helmets require specific curvature or clearance that generic adapters can’t provide.

Final Thoughts: Why a Hard Hat Adapter is a Welding Game-Changer

The hard hat adapter for welding helmets may seem like a simple accessory, but it is a cornerstone of safe and efficient welding in industrial environments. It brings together two essential protective systems into one cohesive unit ensuring compliance, comfort, and peace of mind.

Whether you’re working 30 feet up on scaffolding, inside a ship’s hull, or in a structural steel fabrication yard. This small but mighty tool can mean the difference between frustration and fluency, risk and resilience.